Sources vary on when and where artificial eye manufacturing originated, but there is evidence that the craft can be traced toArtificial eye-making has been practiced since the early days of the Roman and Egyptian empires. These primitive artificial eyes were made of painted clay attached to cloth and worn outside of the eye socket.

Sources vary on when and where artificial eye manufacturing originated, but there is evidence that the craft can be traced toArtificial eye-making has been practiced since the early days of the Roman and Egyptian empires. These primitive artificial eyes were made of painted clay attached to cloth and worn outside of the eye socket.

It wasn’t until centuries later that the first in-socket ocular prosthesis was developed. The first of these were made of solid gold and painted with colored enamel.

In the late renaissance era, Venetian glassmakers started creating glass eyes. The art flourished primarily in France and Germany, where carefully guarded fabricating secrets were handed down from one generation to the next.

In the nineteenth century German Ocularists began to tour the United States, making glass artificial eyes on a national circuit, setting up for several days at a time in one city after another.

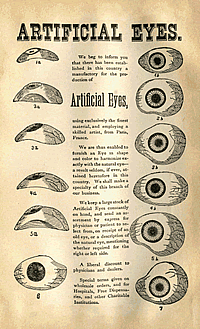

Glass stock eyes were also fit by mail order and out of drawers. Many older patients have told us about going to an office as a child where a technician, with hundreds of glass eyes in cabinets, would fit them with the best fitting eye they could find for them out of the drawer.

Eye manufacture in the United States began about 1850. Eyes continued to be made of glass until the onset of World War II. German glassblowers were no longer touring the United States. Most German goods were being boycotted which compelled the development of an American technology for fabricating artificial eyes.

It is believed that Fritz Jardon in conjunction with American Optical Company worked with the Army and Navy dentist in the original research.

It is believed that Fritz Jardon in conjunction with American Optical Company worked with the Army and Navy dentist in the original research.

Using acrylic resins that formed the basis of fabricating the modern ocular prosthesis, the technology continues today. Since World War II, plastic has become the preferred material for the artificial eye because of it’s durability and longevity.

The plastic used in eye making is a high optical quality acrylic (Methacrylate resin), similar to the material used to make dentures.

Plastic eyes offer several advantages over the glass eyes. They can be impression fit, matching the exact contours of the socket. After the original fabrication by molding, they can be enlarged or otherwise modified as necessary. They can also be attached by titanium pegs to the newer integrated motility implants available today, whereas glass eyes can not.

Plastic artificial eyes can also be polished and cleaned repeatedly when needed and are practically unbreakable. The lifetime of a plastic prosthesis is up to five times longer than that of a glass eye, most of which require replacing every year or two.

Glass artificial eyes must be blown in a flame, are extremely fragile, and when completed can not be polished or altered in any way.

Although it is a common misconception that artificial eyes are made from glass, most artificial eyes produced in the United States are fitted and fabricated by ocularists from Methyl Methacrylate plastic.